Any Fiberglassers around here for Subs?

#1

Any Fiberglassers around here for Subs?

Looking to make a pair of Custom fiberglasss subwoofer boxes.

Not getting much info on 2 other forums, thought I would post links here to them and if you have some ideas, or suggestions on how to do it, please reply here.

(to much to retype so I am posting 2 links to them.)

Thanks

http://www.the12volt.com/installbay/...31375~get~last

http://www.stevemeadedesigns.com/boa...-in-chevy-hhr/

The Fiberglass forum I found is messed up and not allowing new members.

Not getting much info on 2 other forums, thought I would post links here to them and if you have some ideas, or suggestions on how to do it, please reply here.

(to much to retype so I am posting 2 links to them.)

Thanks

http://www.the12volt.com/installbay/...31375~get~last

http://www.stevemeadedesigns.com/boa...-in-chevy-hhr/

The Fiberglass forum I found is messed up and not allowing new members.

#2

Dilsclaimer : I am no expert just a hobbiest.

You will want to make a mold of the window area out to the end of the interior panel. For this take waxpaper and line all of the pocket area with it making sure that it will be every where so that it both protects your interior pieces and helps for removing the mold you make. Once you have this done then you can lay down strips of fiberglass.

Since this mold would be the exact shape and size of the pocket area you can actually use it as your outside layer insted of as an actual mold persay. If you were to use it this way you would want to be sure not to add any layers to the outside of it. AND you could then do all your layers while it is still in the car.

If you plan on covering it in any type of material then you will want to use it as a mold only. If you use it as a mold then you will want to line the inside of it with waxpaper like you did before and then lay down strips again.

Once you have this part built you can then figure out how much more space you have to work with vs how much more you need so that you can figure out where to place the sub and any more space you may need.

You could frame up the pocket area insted BUT you will give up a decent amount of airspace and about 1/2" of mounting depth. Then you also have to make sure that your framing allows for about 3/8" worth of material on all sides inside the pocket but it does work and can let you do all fiberglassing outside of the car which is nice.

For the fiberglass resin I just use the 3M 1 gallon cans and matte from HD or Lowes. You can also go to marine/boat places from what I have heard and get 5 gallon buckets.

You will want to make a mold of the window area out to the end of the interior panel. For this take waxpaper and line all of the pocket area with it making sure that it will be every where so that it both protects your interior pieces and helps for removing the mold you make. Once you have this done then you can lay down strips of fiberglass.

Since this mold would be the exact shape and size of the pocket area you can actually use it as your outside layer insted of as an actual mold persay. If you were to use it this way you would want to be sure not to add any layers to the outside of it. AND you could then do all your layers while it is still in the car.

If you plan on covering it in any type of material then you will want to use it as a mold only. If you use it as a mold then you will want to line the inside of it with waxpaper like you did before and then lay down strips again.

Once you have this part built you can then figure out how much more space you have to work with vs how much more you need so that you can figure out where to place the sub and any more space you may need.

You could frame up the pocket area insted BUT you will give up a decent amount of airspace and about 1/2" of mounting depth. Then you also have to make sure that your framing allows for about 3/8" worth of material on all sides inside the pocket but it does work and can let you do all fiberglassing outside of the car which is nice.

For the fiberglass resin I just use the 3M 1 gallon cans and matte from HD or Lowes. You can also go to marine/boat places from what I have heard and get 5 gallon buckets.

#3

I'd suggest making the box section from MDF of birch, as opposed to entirely fiberglass. Yes, laying glass into the pocket will net you more air space, but do you even need it? Have you figured the max air space you can achieve by boxing the rear, and glassing the front? Fiberglassing in your ride can potentially get very messy, uses allot more material, and will reek of resin.

I build wood /glass boxes as a hobby ( build for my friends, get paid in beer ) and have made enough mistakes over the years to know what not to try. I will be doing boxes of some sort in the same location. I intend on making a wood box base with a flush mount trim to fit the pocket, then fleece and glass. The boxes you mentioned appear to be made this way.

) and have made enough mistakes over the years to know what not to try. I will be doing boxes of some sort in the same location. I intend on making a wood box base with a flush mount trim to fit the pocket, then fleece and glass. The boxes you mentioned appear to be made this way.

You should go ahead and get a 5 gallon bucket of resin. I buy 5 gal buckets and bulk rolls of glass from a local boat shop, much cheaper than you can get from a hardware store. You'd be surprised at how much you end up using, especially once you realize what you can make out of glass.

Any other specific questions, just hit me up, I'll see what I can do

I build wood /glass boxes as a hobby ( build for my friends, get paid in beer

You should go ahead and get a 5 gallon bucket of resin. I buy 5 gal buckets and bulk rolls of glass from a local boat shop, much cheaper than you can get from a hardware store. You'd be surprised at how much you end up using, especially once you realize what you can make out of glass.

Any other specific questions, just hit me up, I'll see what I can do

#4

Here's an example of a similar install. I counter sunk 8" subs under the seats of my panel. Steps taken: made a MDF box base, cut the top to fit the gaps, raised the speaker rings an inch, stretched the fleece, and applied resin. I have since finished the body work, but got no pics.

#5

Thanks for the replies guys. I am gonna copy/paste one of those threads I started as one post here so we are all on the same page, with the same info.

~

Help/info for 1st fiberglass sub enclosures in Chevy HHR

I am gonna give making a pair of custom fiberglass sub boxes a try for my Chevy HHR Panel.

Initial thoughts with my audio/video install was to build some type of sub box amp rack Combo in the rear spare tire well.

But as my daily driver/semi show car that my HHR Panel is to me, I really did not like the idea of loosing the spare tire.

I have been using one Pioneer TS-W3002D4 12 In. Champion Series PRO subwoofer, in a Atrend E12Sv B Box Series 12-Inch Single Vented Subwoofer Enclosure, takes up Alot of room in the back area and hinders hauling stuff in general, and with my added rear seat in my Panel when the 60/40 split rear seat is folded down the sub box slides all over the place in back.

Sliding big sub box has gotta Go and I want Two of the Pioneer 12" subwoofers.

I found a Custom subwoofer install done in another HHR, contacted the owner and he had them custom made at SONUS Car Audio in Clarkesvile TN. Andy2.0 had these made at about a Grand for the pair.

I am gonna try and talk to the guy who made them and see if he will give me some info on how he did them, andy was gonna get me some more pics and some info that he did not post by email, but he hasnt sent them or replied after our initial email.

He must of got busy.

This is what I want to make/recreate.

This is the area in my Panel, the Flat area thats 20X12 is removable.

I'll be ordering up stuff from US Composites. What all should I get to make a pair of these? I have nothing but Time on my hands to give this project a try.

From the looks and from talking to the owner, looks to be a MDF backing and then a MDF Ring mounted off center then fleece stretched over it and resined, add some layers of fiberglass to the inside, and maybe a layer on the outside. and bondo it out smooth.

Originals were covered in black vinyl, and are 10" subs.

(I was a body and fender man for about 12 years full time a long time ago)

Pretty much same kinda design. I know my subs are 12" and I will need to expand the boxes for a little more depth I believe. To get the required •sealed box volume: 0.5-1.0 cubic feet •ported box volume: 0.8-1.6 cubic feet.

I Need / Want my floor space Open, and this type of install will allow that, plus let me use 2 subwoofers.

I just bought and recieved a second Pioneer GM-D8500M mono amp, and will be ordering up a second Pioneer TS-W3002D4 subwoofer and the matching Grill.

These were just done, and posted on a HHR Forum I am on and it's a perfect solution for me and to be able to have a pair of subs without sacrificing floor space or my spare tire, jack and other things I would like to carry in the well area.

As I said, I do have 12 years of body and fender, and auto painter experience, I have a complete woodworking shop in my garage, 6HP 80 Gallon air compressor, sandblasting cabinet, fully tooled to do just about anything, garage is Heated and is AC'ed as well.

I just never made a subwoofer enclosure before. Not saying it won't be hard to do, just that I can't afford to spend that kinda cash having them custon made.

I gutted the interior and sound deadend 90% of the interior roof to floor, doors are done with a layer on the inside outer door skin and then the door is sealed up and a layer on it directly behind the interior door panels, roof and floor are 100% covered, rear spare tire area is 100% covered as are the rear quarter panels.I did not tear the dash out to get in behind it and the firewall, to much work to do that. Huge improvement in the car overall. In the area were the door speakers are I did add a 12"X12" area with 3 layers (4 total overall) directly behind each of the speakers.

Ideas and thoughts on how to do this is what I am looking for, not sure how to achieve the outer rim area that fits around the outside edges.

Not sure how much materials I will need, 2 gallons of resin, sheet of 3/4" MDF, and how much and what kinds of fiberglass should I get?

I am home all day, so I got nothing better to do than play with my little HHR Panel.

I'll make one to get my subwoofer up out of the way first, completeing it fully, then make the second side.

Gotta have a Pair so both sides Match.

Bought so far for my little project-

Jasper #200 Circle Guide (Amazon)

Hit up Home Depot for these-

1LB. Box of SPAX Hardwood and MDF Screws #6 x 1.5 inches long(nice small heads)

2 SPAX T20 Driver Tips

2- 2'X4' 3/4" MDF

1- 2'X4' 1/2" MDF

-1 2"X4" 1/4" MDF

3- 1 Quart Multi Mix Containers

3 bags- 3M 8 sq.ft. fiberglass mat (i'll be buying more mat from USC when I place my 1 gallon resin order and other supplys)

1 bag- 3M 8 sq.ft. fiberglass cloth

4 Rolls of 2" 3M Blue Painters Tape

I'll be buying a gallon of resin and other supplies from USComposites.com, they no longer carry the B-440 Premium Polyester Layup Resin , should I just get the 435 instead? Is there a Replacement for the B-440?

I have routers, table saws, drill presses, large stand alone belt sander, jointers, drum sander, 14" disk sander, air compressor and a full assortment of air driven tools, fully tooled garage.

As a former Body & Fender man, the actual fiberglassin and bondo work is the easy part for me, looking mainly for suggestions on building the sub box itself, fabricating it. I just never built a custom formed sub box before.

I won't cut any corners to make these, I'll buy whatever I need that I don't already own.

USComposites Order is looking like this so far. Any thoughts on it?

10 yards FG-10538 38" Width 1-1/2oz Chopped Strand Mat $2.55 a Yard = $25.50

1 Gallon SM-435100 - 435 Standard Polyester Layup Resin < size=2 face=Arial>< size=2 face=Arial>$ 30.50

SM-STY025 - Styrene Quart(32oz) $6.75

SM-MEKP080 - MEKP Hardener 8oz $5.50

SM-SWAX02 - Surfacing Wax 2oz Bottle $2.25

FR-1213A - Fiberglass Detail Roller 3/8" x 3" $6.70

$77.20 Plus Shipping

Locally bought stuff.

I am rough sketch drawing something up, and will post it with some questions soon.

New to Sketchbook Pro, so it won't be fancy or anything.

I got some ideas, once I post the rough bad sketch i'll run them by you guys.

Thanks

~

Help/info for 1st fiberglass sub enclosures in Chevy HHR

I am gonna give making a pair of custom fiberglass sub boxes a try for my Chevy HHR Panel.

Initial thoughts with my audio/video install was to build some type of sub box amp rack Combo in the rear spare tire well.

But as my daily driver/semi show car that my HHR Panel is to me, I really did not like the idea of loosing the spare tire.

I have been using one Pioneer TS-W3002D4 12 In. Champion Series PRO subwoofer, in a Atrend E12Sv B Box Series 12-Inch Single Vented Subwoofer Enclosure, takes up Alot of room in the back area and hinders hauling stuff in general, and with my added rear seat in my Panel when the 60/40 split rear seat is folded down the sub box slides all over the place in back.

Sliding big sub box has gotta Go and I want Two of the Pioneer 12" subwoofers.

I found a Custom subwoofer install done in another HHR, contacted the owner and he had them custom made at SONUS Car Audio in Clarkesvile TN. Andy2.0 had these made at about a Grand for the pair.

I am gonna try and talk to the guy who made them and see if he will give me some info on how he did them, andy was gonna get me some more pics and some info that he did not post by email, but he hasnt sent them or replied after our initial email.

He must of got busy.

This is what I want to make/recreate.

This is the area in my Panel, the Flat area thats 20X12 is removable.

I'll be ordering up stuff from US Composites. What all should I get to make a pair of these? I have nothing but Time on my hands to give this project a try.

From the looks and from talking to the owner, looks to be a MDF backing and then a MDF Ring mounted off center then fleece stretched over it and resined, add some layers of fiberglass to the inside, and maybe a layer on the outside. and bondo it out smooth.

Originals were covered in black vinyl, and are 10" subs.

(I was a body and fender man for about 12 years full time a long time ago)

Pretty much same kinda design. I know my subs are 12" and I will need to expand the boxes for a little more depth I believe. To get the required •sealed box volume: 0.5-1.0 cubic feet •ported box volume: 0.8-1.6 cubic feet.

I Need / Want my floor space Open, and this type of install will allow that, plus let me use 2 subwoofers.

I just bought and recieved a second Pioneer GM-D8500M mono amp, and will be ordering up a second Pioneer TS-W3002D4 subwoofer and the matching Grill.

These were just done, and posted on a HHR Forum I am on and it's a perfect solution for me and to be able to have a pair of subs without sacrificing floor space or my spare tire, jack and other things I would like to carry in the well area.

As I said, I do have 12 years of body and fender, and auto painter experience, I have a complete woodworking shop in my garage, 6HP 80 Gallon air compressor, sandblasting cabinet, fully tooled to do just about anything, garage is Heated and is AC'ed as well.

I just never made a subwoofer enclosure before. Not saying it won't be hard to do, just that I can't afford to spend that kinda cash having them custon made.

I gutted the interior and sound deadend 90% of the interior roof to floor, doors are done with a layer on the inside outer door skin and then the door is sealed up and a layer on it directly behind the interior door panels, roof and floor are 100% covered, rear spare tire area is 100% covered as are the rear quarter panels.I did not tear the dash out to get in behind it and the firewall, to much work to do that. Huge improvement in the car overall. In the area were the door speakers are I did add a 12"X12" area with 3 layers (4 total overall) directly behind each of the speakers.

Ideas and thoughts on how to do this is what I am looking for, not sure how to achieve the outer rim area that fits around the outside edges.

Not sure how much materials I will need, 2 gallons of resin, sheet of 3/4" MDF, and how much and what kinds of fiberglass should I get?

I am home all day, so I got nothing better to do than play with my little HHR Panel.

I'll make one to get my subwoofer up out of the way first, completeing it fully, then make the second side.

Gotta have a Pair so both sides Match.

Bought so far for my little project-

Jasper #200 Circle Guide (Amazon)

Hit up Home Depot for these-

1LB. Box of SPAX Hardwood and MDF Screws #6 x 1.5 inches long(nice small heads)

2 SPAX T20 Driver Tips

2- 2'X4' 3/4" MDF

1- 2'X4' 1/2" MDF

-1 2"X4" 1/4" MDF

3- 1 Quart Multi Mix Containers

3 bags- 3M 8 sq.ft. fiberglass mat (i'll be buying more mat from USC when I place my 1 gallon resin order and other supplys)

1 bag- 3M 8 sq.ft. fiberglass cloth

4 Rolls of 2" 3M Blue Painters Tape

I'll be buying a gallon of resin and other supplies from USComposites.com, they no longer carry the B-440 Premium Polyester Layup Resin , should I just get the 435 instead? Is there a Replacement for the B-440?

I have routers, table saws, drill presses, large stand alone belt sander, jointers, drum sander, 14" disk sander, air compressor and a full assortment of air driven tools, fully tooled garage.

As a former Body & Fender man, the actual fiberglassin and bondo work is the easy part for me, looking mainly for suggestions on building the sub box itself, fabricating it. I just never built a custom formed sub box before.

I won't cut any corners to make these, I'll buy whatever I need that I don't already own.

USComposites Order is looking like this so far. Any thoughts on it?

10 yards FG-10538 38" Width 1-1/2oz Chopped Strand Mat $2.55 a Yard = $25.50

1 Gallon SM-435100 - 435 Standard Polyester Layup Resin < size=2 face=Arial>< size=2 face=Arial>$ 30.50

SM-STY025 - Styrene Quart(32oz) $6.75

SM-MEKP080 - MEKP Hardener 8oz $5.50

SM-SWAX02 - Surfacing Wax 2oz Bottle $2.25

FR-1213A - Fiberglass Detail Roller 3/8" x 3" $6.70

$77.20 Plus Shipping

Locally bought stuff.

I am rough sketch drawing something up, and will post it with some questions soon.

New to Sketchbook Pro, so it won't be fancy or anything.

I got some ideas, once I post the rough bad sketch i'll run them by you guys.

Thanks

#8

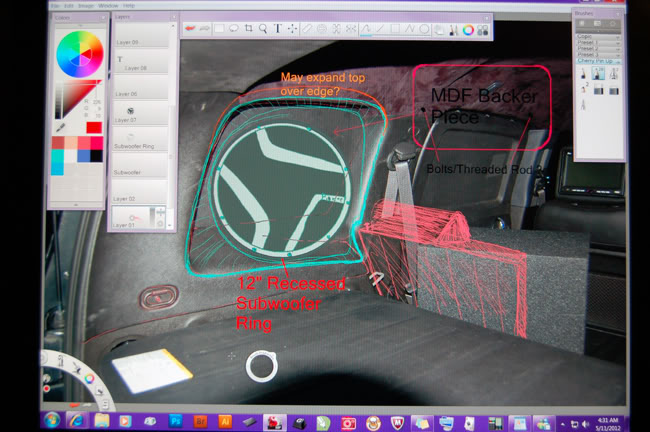

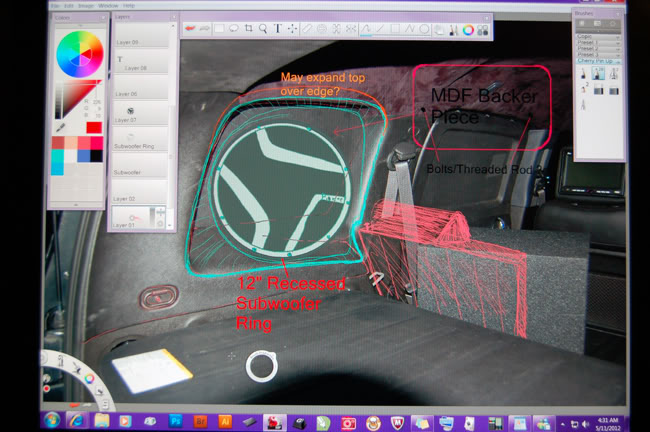

A very ROUGH sketch here over a picture, just got Sketchbook Pro when I bought my Wacom Cintiq 21UX, so I am learning how the software works.

My thoughts so far on building it are-

The interior panel has a Flat area that GM just added a seperate piece to Cover were a window would have been in the AA5's and the Panels.

Remove that 20"x12" piece (rough dimensions) and that leaves you access to the body.

I'll have to remove the interior panel and remove that flat piece to see Exactly how I could Bolt the 3/4" MDF Backer in place so once the sub box is Completed I can reach in through the 12" opening and LOCK it down, and remove when wanted.

I may be able to add a piece of metal going across the back by either welding or pop riveting it in place and have bolts facing into the box area as a locking point bolting it in place, or, maybe using Large washers, bolt into the side area around were the glass would have been.

The 12" subs are pretty darn Heavy and deep, so I will have to Extend the "Ring" out into the interior space. I'll know by how much once I take some more measurements.

Should the subs Face straight out "Level" facing each other, or most likely will need to be slightly facing towards the rear ?

BONDING - Bonding the Fiberglass to the MDF, Just how STRONG of a BOND does just slathering fiberglass and resin over the top of a MDF piece provide?

Planning on using 3M Blue 2" wide painters tape, to fully tape out the "cubbie" area and fully drapping visqueen plastic sheeting all over top and bottom surrounding area.

Then placing the MDF backer in place and start my fiberglassing out and beyound the rectangle area so it can later be Trimmed down for a perfectly shaped Fit.

Then set the depth and the angle of the subwoofer ring, then stretch my material over the top, resin it, then start layering fiberglass matting on the Inside doing 2 layers at a time, letting it cure/harden and layering another 2 layers letting it harden then another 2 layers for about 6 layers total.

I can then work on the outside top area that will be Seen. Still not sure if I will paint and buff it out, or cover it in black vinyl, or even the matching suede I used on my headliner.

If you Look really Close to the Original, you can see some shaped angles set in the top. Anyone have thoughts on how that was made up?

I bought 3/4", 1/2" and 1/4" MDF.

I was thinking it could be a cutout to fit flush with the interior panels outtter edges, and a layered layer of thin MDF, with the Ring extended beyond that and then the cloth drapped/stretched over the top, then resined?

Thanks

My thoughts so far on building it are-

The interior panel has a Flat area that GM just added a seperate piece to Cover were a window would have been in the AA5's and the Panels.

Remove that 20"x12" piece (rough dimensions) and that leaves you access to the body.

I'll have to remove the interior panel and remove that flat piece to see Exactly how I could Bolt the 3/4" MDF Backer in place so once the sub box is Completed I can reach in through the 12" opening and LOCK it down, and remove when wanted.

I may be able to add a piece of metal going across the back by either welding or pop riveting it in place and have bolts facing into the box area as a locking point bolting it in place, or, maybe using Large washers, bolt into the side area around were the glass would have been.

The 12" subs are pretty darn Heavy and deep, so I will have to Extend the "Ring" out into the interior space. I'll know by how much once I take some more measurements.

Should the subs Face straight out "Level" facing each other, or most likely will need to be slightly facing towards the rear ?

BONDING - Bonding the Fiberglass to the MDF, Just how STRONG of a BOND does just slathering fiberglass and resin over the top of a MDF piece provide?

Planning on using 3M Blue 2" wide painters tape, to fully tape out the "cubbie" area and fully drapping visqueen plastic sheeting all over top and bottom surrounding area.

Then placing the MDF backer in place and start my fiberglassing out and beyound the rectangle area so it can later be Trimmed down for a perfectly shaped Fit.

Then set the depth and the angle of the subwoofer ring, then stretch my material over the top, resin it, then start layering fiberglass matting on the Inside doing 2 layers at a time, letting it cure/harden and layering another 2 layers letting it harden then another 2 layers for about 6 layers total.

I can then work on the outside top area that will be Seen. Still not sure if I will paint and buff it out, or cover it in black vinyl, or even the matching suede I used on my headliner.

If you Look really Close to the Original, you can see some shaped angles set in the top. Anyone have thoughts on how that was made up?

I bought 3/4", 1/2" and 1/4" MDF.

I was thinking it could be a cutout to fit flush with the interior panels outtter edges, and a layered layer of thin MDF, with the Ring extended beyond that and then the cloth drapped/stretched over the top, then resined?

Thanks

#9

#10

Thanks for the offer, but my Budget is now TRASHED.

I need to make them saving as much as I can.

These and then Finally moving on to my very Last Mod/Project of the Supercharger install and I am DONE.

My wallet is so thin I can barely see it anymore.

I'd have to ship Both large upper interior pieces, at least one subwoofer and one of the subwoofer Grills. Unless you'd make it from your HHR, they are all the same LS, LT, SS interior wise in that upper quarter area.

Updated my US C. order to-

1.5 OZ. Chopped Strand Mat, 38" wide X 10 Yards

2 Gallons 435 Standard Poly Resin

1 Quart Styrene (Resin Thinner)

4 OZ. MEKP Hardener (Extra besides the included hardener with each gallon)

2 OZ. Surfacing Wax (added to last resin layers to aide in Sanding)

3/8" X 3" Fiberglass Detail Roller

I plan on placing the order Today.

If I end up needing More Resin, I will get it Locally.

I will use 1 gallon of the 435 for each side (Non Waxed) making the first one I will see just how far 1 gallon goes, If I know I will need more, I'll run over to my auto paint supplier and grab a gallon for final coats/layers that will be waxed to help with sanding. At least this way I will have a good quality resin as my base.

And the thicker locally bought resins, I can thin slightly with the Styrene thinner I am buying.