Wastegate

#11

P0299 is a code for underboost. One member reported that his was caused by a boost leak, specifically one of the charge pipes was split. There is a link to a homemade boost leak tester somewhere, I think it's in the how-to for engine leak down test. I'm on my phone or I'd post the link for you.

You can search here with the search window at the top of every page, That's p zero 299. It may also have to do with the bypass valve. The diaphragm could be split or the spring broken. It's not terribly difficult to remove the cover and inspect it. Or it may be the bypass solenoid, mounted on the intake manifold.

You can search here with the search window at the top of every page, That's p zero 299. It may also have to do with the bypass valve. The diaphragm could be split or the spring broken. It's not terribly difficult to remove the cover and inspect it. Or it may be the bypass solenoid, mounted on the intake manifold.

I have pressure tested all plumbing and the inter cooler. I have visual checked the bypass valve, but I can open & close it with my mouth on the vacuum hose. I don't have a vacuum tester or even know the specs. on the bypass valve either. But if I can move it with my lungs, it seems like it should take more vacuum than that. You maybe right about the spring. Do you know the amount of vacuum I should have?

#13

Wastegates

When a turbocharger’s exhaust-driven turbine wheel spins fast enough to produce the desired level of boost, a wastegate is typically used to allow the excess exhaust pressure to divert around the turbine wheel. By opening the wastegate (typically boost-pressure referenced), exhaust pressure bypasses the turbo’s turbine wheel to prevent the turbo from reaching an unsafe speed. You’ll find external wastegates on the exhaust (hot) side of turbo plumbing between the turbocharger turbine wheel and the exhaust manifold—or sometimes in the exhaust manifold itself—where it can get exhaust upstream of the turbo and route it back into the exhaust downstream of the turbo. Not all turbocharger systems need wastegates, such as late-model turbos with variable-geometry turbine housings (which can provide similar capability).

In its at-rest state, a wastegate is closed and boost pressure can be controlled by varying the pressure of the spring holding it closed. A wastegate can also work in concert with a boost controller to improve boost response by staying closed to a higher boost threshold.

Blow-Off Valves

Located on the pressurized intake (cold) side of the turbo plumbing, blow-off valves (BOVs), like wastegates, are normally closed and open to bleed off boost pressure. Their main job is to prevent the pressure in the intake tract from backing up and causing compressor surge when engine speed changes abruptly—like when the throttle closes during a shift. When a BOV is vented to atmosphere, it produces a distinctive hissing sound, and when a BOV isn’t used or is of insufficient size, the compressor surges and makes a chirping or rattling sound. Compressor surge can put stress on the compressor and its bearings, shortening its life.

Like RJ suggests Do yourself a favor, don't mess with the wastegate, or your gonna have more problems than you have now.

When a turbocharger’s exhaust-driven turbine wheel spins fast enough to produce the desired level of boost, a wastegate is typically used to allow the excess exhaust pressure to divert around the turbine wheel. By opening the wastegate (typically boost-pressure referenced), exhaust pressure bypasses the turbo’s turbine wheel to prevent the turbo from reaching an unsafe speed. You’ll find external wastegates on the exhaust (hot) side of turbo plumbing between the turbocharger turbine wheel and the exhaust manifold—or sometimes in the exhaust manifold itself—where it can get exhaust upstream of the turbo and route it back into the exhaust downstream of the turbo. Not all turbocharger systems need wastegates, such as late-model turbos with variable-geometry turbine housings (which can provide similar capability).

In its at-rest state, a wastegate is closed and boost pressure can be controlled by varying the pressure of the spring holding it closed. A wastegate can also work in concert with a boost controller to improve boost response by staying closed to a higher boost threshold.

Blow-Off Valves

Located on the pressurized intake (cold) side of the turbo plumbing, blow-off valves (BOVs), like wastegates, are normally closed and open to bleed off boost pressure. Their main job is to prevent the pressure in the intake tract from backing up and causing compressor surge when engine speed changes abruptly—like when the throttle closes during a shift. When a BOV is vented to atmosphere, it produces a distinctive hissing sound, and when a BOV isn’t used or is of insufficient size, the compressor surges and makes a chirping or rattling sound. Compressor surge can put stress on the compressor and its bearings, shortening its life.

Like RJ suggests Do yourself a favor, don't mess with the wastegate, or your gonna have more problems than you have now.

#14

If you have no boost leak, I would say to check for leaks in the small tubing attached to the bypass solenoid. 3 lines connecting the vacuum tank, the bypass valve, and the lower Tmap sensor, to the solenoid on the intake manifold. There is also a vacuum line connecting the intake manifold to the vacuum tank. The vacuum tank itself could be leaking.

This testing is all cheap/free is why I mention it, and could possibly be the cause of your problem. But I think the higher probability is that the bypass solenoid is bad. It operates on duty cycle, which someone else who understands it better will explain if necessary.

The bypass spring could potentially be weak, but I think that is also low probability.

This testing is all cheap/free is why I mention it, and could possibly be the cause of your problem. But I think the higher probability is that the bypass solenoid is bad. It operates on duty cycle, which someone else who understands it better will explain if necessary.

The bypass spring could potentially be weak, but I think that is also low probability.

#15

There are a couple of links in this post where you can buy a bypass solenoid. You can also search the internet with the part number on the linked-to pages.

Here is the link to the post.

https://www.chevyhhr.net/forums/ss-s...e4/#post797763

Here is the link to the post.

https://www.chevyhhr.net/forums/ss-s...e4/#post797763

#16

I would try the boost solenoid 1st. Do you have the boost sensors/GMTU upgrade done to yours? IF so, was it one of the first ones where the wires were crimped instead of the adapter connectors? Mine was one of the first onse and I had issues with the crimp connectors where it would boost and then drop. I removed the crimp connectors and then soldered the connections and the problems went away.

#17

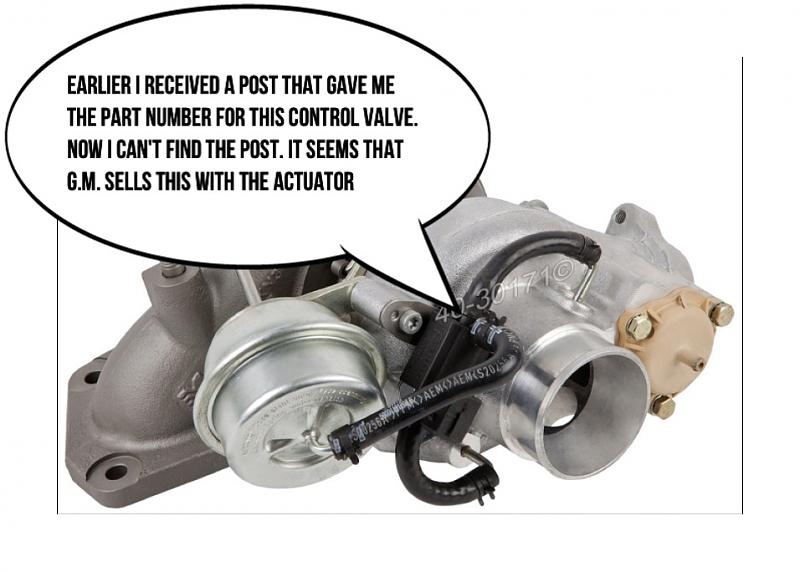

This old picture I labeled may help out.

The picture below shows the vacuum hose routing and direction of vacuum pull.

Yellow: goes to and from the canister under the manifold.

Blue : is the hose to the lower charge pipe(nipple next to the lower Tmap sensor )

Red : is the hose to the bypass valve on the turbo.

The picture below shows the vacuum hose routing and direction of vacuum pull.

Yellow: goes to and from the canister under the manifold.

Blue : is the hose to the lower charge pipe(nipple next to the lower Tmap sensor )

Red : is the hose to the bypass valve on the turbo.

#18

I would try the boost solenoid 1st. Do you have the boost sensors/GMTU upgrade done to yours? IF so, was it one of the first ones where the wires were crimped instead of the adapter connectors? Mine was one of the first onse and I had issues with the crimp connectors where it would boost and then drop. I removed the crimp connectors and then soldered the connections and the problems went away.

No Dennis, it is totally factory stock. I have had the boost sensor on the work bench testing it with 12V to the terminals. When I applied voltage, there was no sound and blowing into the nipple that hooks to turbo output the air would go out the nipple, which is coming out of the boost solenoid 90 degrees, and never would output out of bleed off nipple. As a result I am sending the total boost pressure to the wastegate actuator. With your help I now realize that the wastegate actuator spring is not supposed to be able to withstand 21 psi. It is most likely good as it is. I should be able to replace the boost sensor, and live happily ever after. Thank you all so Much.

#19