nrvous1's ZZP Header Thread

#1

Mocking up my exhaust for the install this weekend and noticed a gap between the flanges from the zzp downpipe to the GMPP (Borla) catback. Will this be a problem when installing? I didn't want to start a new threat so I figured I would post this here.

Last edited by 843de; 12-08-2015 at 11:31 PM. Reason: Fixed image link.

#3

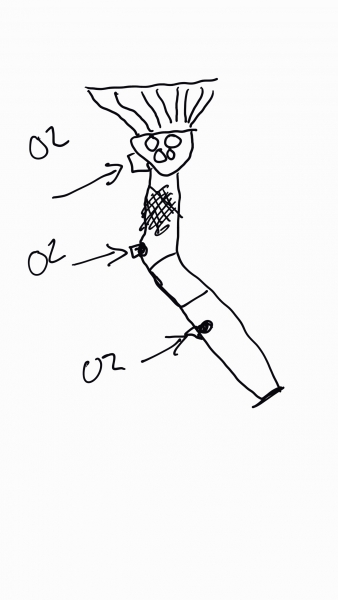

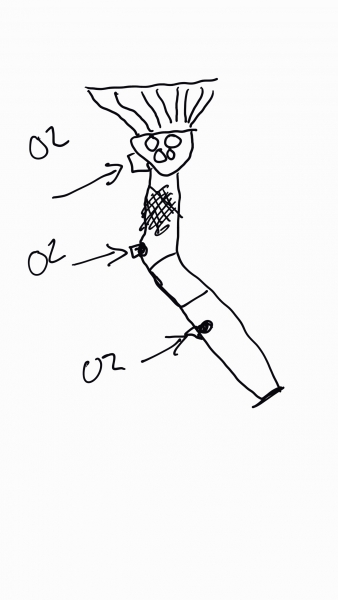

Ok, I have another exhaust question. While looking at the zzp header and down pipe I see there are 3 o2 sensor bungs. So, I ordered a bung plug through zzp and also emailed asking which o2 bung I would need to plug. The factory o2's are on the down pipe and not the stock exhaust manifold. I figured I would need to plug the o2 bung on the zzp header and use the 2 on the zzp down pipe just like the factory pipe. But, after emailing zzp they told me to plug the top o2 bung on the down pipe and use the bung on the header instead. I have attached a drawing of the header and down pipe with the location of the o2's. Can anyone confirm which holes to place the o2's in?

Last edited by RJ_RS_SS_350; 03-12-2017 at 01:23 AM.

#4

Ok. Started late with the header, dp and catback install. The catback I got in place in about 30 minutes, but I haven't tightened anything up until I get the dp ready to tighten as well. I ran into a problem while installing the header. The header bolt/nut on the #1 position came completely out of the head. I can't thread the threaded portion back into the block with the nut still on. I'm going to remove the nut and try threading the end back into the head. Can anyone chime in on this and give me any tips when doing this?

Edit: Here's a pic of the bolt I was talking about.

Edit: Here's a pic of the bolt I was talking about.

Last edited by RJ_RS_SS_350; 03-12-2017 at 01:19 AM.

#5

Sometimes that'll happen nrvous1, you try to break a nut loose from a stud and you get the nut and stud too.

You might booger up the stud getting the nut off, but your local auto parts store can help, the best thing to do is soak it in penetrating oil overnight.

Once the stud and nut have given up their love affair, reinstall the stud and tighten it to 89 in lbs/7.4 ft lbs. Or minus a torque wrench, just tighten the stud until it's "snug", you dont have to kill it.

The header nuts get tightened to 106 in lbs/8.9 ft lbs, or whatever spec ZZP calls for.

Again, if you're lacking a torque wrench, you're looking for "snug" that's it, remember too much force will clean the threads right out of the cylinder head.

That would really wreck your weekend.

You might booger up the stud getting the nut off, but your local auto parts store can help, the best thing to do is soak it in penetrating oil overnight.

Once the stud and nut have given up their love affair, reinstall the stud and tighten it to 89 in lbs/7.4 ft lbs. Or minus a torque wrench, just tighten the stud until it's "snug", you dont have to kill it.

The header nuts get tightened to 106 in lbs/8.9 ft lbs, or whatever spec ZZP calls for.

Again, if you're lacking a torque wrench, you're looking for "snug" that's it, remember too much force will clean the threads right out of the cylinder head.

That would really wreck your weekend.

#7

Run the stud in by hand nrvous1, if it threads in cleanly without feeling like it wants to cross thread, then you can skip the thread chaser.

Oldblue's suggestion is a good one if the threads got "boogered up", but looking at the stud closely, I'd say you just wound the stud out of the head with the nut. Been there, done that, swore a blue streak everytime.

"Chasing" threads on aluminum heads and blocks really only needs to be done if the threads are damaged, because by chasing the threads you'll increase the hole size by a small amount and then the stud will fit loosely and lose some clamping ability.

GM used (Medium Strength Blue Loctite 242) on the exhaust manifold studs from the factory, and I can see some residue on the threads. Whether you choose to use Loctite 242 when you wind the stud in is up to you, but if you do, use it sparingly...just a drop on the threads.

Don't drown the stud or squirt the Loctite in the hole, I've seen folks do that, and the next thing they hear is a snap as the head cracks around the hole.

Since your Header Install has taken on a life of its own nrvous1, I've gathered up the posts and compiled them into a new thread for you. That way everything is kept together instead of getting spread out over four pages of the "What Did" thread.

Oldblue's suggestion is a good one if the threads got "boogered up", but looking at the stud closely, I'd say you just wound the stud out of the head with the nut. Been there, done that, swore a blue streak everytime.

"Chasing" threads on aluminum heads and blocks really only needs to be done if the threads are damaged, because by chasing the threads you'll increase the hole size by a small amount and then the stud will fit loosely and lose some clamping ability.

GM used (Medium Strength Blue Loctite 242) on the exhaust manifold studs from the factory, and I can see some residue on the threads. Whether you choose to use Loctite 242 when you wind the stud in is up to you, but if you do, use it sparingly...just a drop on the threads.

Don't drown the stud or squirt the Loctite in the hole, I've seen folks do that, and the next thing they hear is a snap as the head cracks around the hole.

Since your Header Install has taken on a life of its own nrvous1, I've gathered up the posts and compiled them into a new thread for you. That way everything is kept together instead of getting spread out over four pages of the "What Did" thread.

#9

Thanks guys for all the help and suggestions.

I tried different ways if trying to get the nut off of the stud and started to smash the threads of the stud. What I'm going to do is start ever so slightly tighten the other header bolts to pull the header closer to the head and see it I can thread the stud back in by hand. I tried yesterday, but I couldn't get the threads started. I figured if the bolt is seized on the stud I should be able to thread the stud back into the head and torque everything down. I could be wrong though. I was also thinking of going to the auto parts store or even lowes or home depot and getting a grade 8 bolt or similar and threading that in. Any thoughts?

I tried different ways if trying to get the nut off of the stud and started to smash the threads of the stud. What I'm going to do is start ever so slightly tighten the other header bolts to pull the header closer to the head and see it I can thread the stud back in by hand. I tried yesterday, but I couldn't get the threads started. I figured if the bolt is seized on the stud I should be able to thread the stud back into the head and torque everything down. I could be wrong though. I was also thinking of going to the auto parts store or even lowes or home depot and getting a grade 8 bolt or similar and threading that in. Any thoughts?

#10

Don't try to reuse that stud if the nut is stuck on. Too easy to mess up the threads on the receiving end.

Go to Lowes or Home Depot and look in their specialty drawers in the nut/bolt isle. I've made many, many trips there looking for stuff for my projects.

Just picked up a metric stud the other day for my Echo chainsaw bar. Cheaper than trying to get one from Echo parts.

Try to get one with that collar in the middle. When you install it, that collar keeps you from bottoming out the stud.

Put 2 nuts snugged togeather on the far end. That gives you something to put a wrench on to install the stud. After the stud is tightened down, take 2 wrenches to loosen the nuts, then remove them to finish your job.

Go to Lowes or Home Depot and look in their specialty drawers in the nut/bolt isle. I've made many, many trips there looking for stuff for my projects.

Just picked up a metric stud the other day for my Echo chainsaw bar. Cheaper than trying to get one from Echo parts.

Try to get one with that collar in the middle. When you install it, that collar keeps you from bottoming out the stud.

Put 2 nuts snugged togeather on the far end. That gives you something to put a wrench on to install the stud. After the stud is tightened down, take 2 wrenches to loosen the nuts, then remove them to finish your job.