Misfire and turbo issues: yet another thread

#12

A code P0304 may mean that one or more of the following has happened: Faulty spark plug or wire Faulty coil (pack) Faulty oxygen sensor(s) Faulty fuel injector Burned exhaust valve Faulty catalytic converter(s) Running out of fuel Poor compression Defective computer

Read more at: OBD-II Trouble Code: P0304 Cylinder 4 Four Misfire Detected

Copyright OBD-Codes.com

Read more at: OBD-II Trouble Code: P0304 Cylinder 4 Four Misfire Detected

Copyright OBD-Codes.com

By exclusion:

Faulty spark plug: swapped and replaced, no difference

wire: maybe harness to coil

Faulty coil (pack): coils swapped, same cylinder misfire

Faulty oxygen sensor(s): mmm..not familiar with those...would they throw O2 sensor codes? How could 1 sensor affect the same cylinder. how many are there? where?

Faulty fuel injector: it's a possibility

Burned exhaust valve: if it was the case, shouldn't it throw the code also with lower boost but high RPM?

Faulty catalytic converter: mmm.. same as O2 sensor, How could that affect the same cylinder

Running out of fuel: tank always with plenty of gas

Poor compression: compression is OK (IMHO)

Defective computer: or flash maybe?

The questions above are out of ignorance on my side, not familiar with codes/computers/technology :)

#13

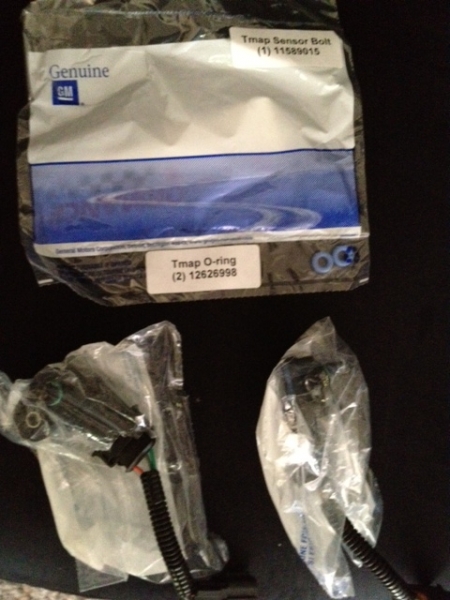

Green O-ring on the Tmap sensor ?

Well, that's odd. Both my sensors came with the same blue O-ring.

Attachment 17490

Well, that's odd. Both my sensors came with the same blue O-ring.

Attachment 17490

My sensors look different... both looks the same, like this:

3 Bar MAP Sensor 55206797

I read somewhere about green and blue, being blue the correct ones because thicker.

I swapped sensors (top with bottom) without replacing the orings, and the issue was still the same.

Are your sensors OEM or GM upgrade (Bosch)?

#14

My sensors look different... both looks the same, like this:

3 Bar MAP Sensor 55206797

I read somewhere about green and blue, being blue the correct ones because thicker.

I swapped sensors (top with bottom) without replacing the orings, and the issue was still the same.

Are your sensors OEM or GM upgrade (Bosch)?

3 Bar MAP Sensor 55206797

I read somewhere about green and blue, being blue the correct ones because thicker.

I swapped sensors (top with bottom) without replacing the orings, and the issue was still the same.

Are your sensors OEM or GM upgrade (Bosch)?

I was just trying to show that with either type of sensor, the blue O-rings should be the correct ones.

#16

[QUOTE=firemangeorge;785168][QUOTE=DrLoch

"If you have the stage kit you should be boosting more than what you are seeing, you should be in the 21 - 23 PSI range. Look for a loose hose or a cracked tube."

Uh, not exactly correct. Don't need to let the OP think something is wrong because his doesn't peak at 21-23. Mine hit's at best 19-20 with the GMTU. And yes, everything on mine is working correctly and hitting the power numbers it should be. I have the plug/play harness on mine. No crimps/solder.[/QUOTE]

Understand, so as to not mis-inform anyone, let me rephrase my response then, MINE a 2008, was boosting high numbers after the upgrade. Here's a thread about what others have/were seeing in terms of boost, https://www.chevyhhr.net/forums/2-0l...k-boost-29252/ . I have installed a Aeroforce gauge in place of the factory gauge Aeroforce Technology Inc | Products - Interceptor and the numbers I mentioned are numbers that I have seen when I've logged it before I made my adjustments.

Here is more information about the OP's problem. P0302,P0303,P0304 misfire codes - Cobalt SS Network

FWIW mine never threw a code of any sort it.

"If you have the stage kit you should be boosting more than what you are seeing, you should be in the 21 - 23 PSI range. Look for a loose hose or a cracked tube."

Uh, not exactly correct. Don't need to let the OP think something is wrong because his doesn't peak at 21-23. Mine hit's at best 19-20 with the GMTU. And yes, everything on mine is working correctly and hitting the power numbers it should be. I have the plug/play harness on mine. No crimps/solder.[/QUOTE]

Understand, so as to not mis-inform anyone, let me rephrase my response then, MINE a 2008, was boosting high numbers after the upgrade. Here's a thread about what others have/were seeing in terms of boost, https://www.chevyhhr.net/forums/2-0l...k-boost-29252/ . I have installed a Aeroforce gauge in place of the factory gauge Aeroforce Technology Inc | Products - Interceptor and the numbers I mentioned are numbers that I have seen when I've logged it before I made my adjustments.

Here is more information about the OP's problem. P0302,P0303,P0304 misfire codes - Cobalt SS Network

FWIW mine never threw a code of any sort it.

Last edited by DrLoch; 08-08-2015 at 07:20 AM. Reason: Changed verbiage

#18

[QUOTE=DrLoch;785200]

Understand, so as to not mis-inform anyone, let me rephrase my response then, MINE a 2008, was boosting high numbers after the upgrade. Here's a thread about what others have/were seeing in terms of boost, https://www.chevyhhr.net/forums/2-0l...k-boost-29252/ . I have installed a Aeroforce gauge in place of the factory gauge Aeroforce Technology Inc | Products - Interceptor and the numbers I mentioned are numbers that I have seen when I've logged it before I made my adjustments.

Here is more information about the OP's problem. P0302,P0303,P0304 misfire codes - Cobalt SS Network

FWIW mine never threw a code of any sort it.

Read the topic on the Cobalt forum... actually I wanted to look into the intake with an inspection camera... a friend might have one.

Also... I have a few log files, but they don't "tell" me anything opening them in EXEL.

I guess I need some other software to read them? And I'm not sure what to look at... never dealt with log files.

Somebody suggested a burnt exhaust valve. If it was the valve, wouldn't I have a misfire, always, regardless of turbo PSI? I can drive the car or rev it up in N at 5000rpm and no misfire

Anyway, wires will be soldered.. I just have to find the time

*edit: I will also order a new set of o-rings

Understand, so as to not mis-inform anyone, let me rephrase my response then, MINE a 2008, was boosting high numbers after the upgrade. Here's a thread about what others have/were seeing in terms of boost, https://www.chevyhhr.net/forums/2-0l...k-boost-29252/ . I have installed a Aeroforce gauge in place of the factory gauge Aeroforce Technology Inc | Products - Interceptor and the numbers I mentioned are numbers that I have seen when I've logged it before I made my adjustments.

Here is more information about the OP's problem. P0302,P0303,P0304 misfire codes - Cobalt SS Network

FWIW mine never threw a code of any sort it.

Read the topic on the Cobalt forum... actually I wanted to look into the intake with an inspection camera... a friend might have one.

Also... I have a few log files, but they don't "tell" me anything opening them in EXEL.

I guess I need some other software to read them? And I'm not sure what to look at... never dealt with log files.

Somebody suggested a burnt exhaust valve. If it was the valve, wouldn't I have a misfire, always, regardless of turbo PSI? I can drive the car or rev it up in N at 5000rpm and no misfire

Anyway, wires will be soldered.. I just have to find the time

*edit: I will also order a new set of o-rings

#19

My suggestion would be to solder the connections 1st and see what happens. I'm not familiar with the logging capabilities of the RPD to be able to comment, hopefully someone else can jump in.

I use HPTuners to do all my logging and adjustments.

I use HPTuners to do all my logging and adjustments.

#20

Yes never mind the computer stuff for now! Eliminate the know possible basic mechanical things one at a time!

Solder connections first!

Orings if required second!

Injectors if required third!

Solder connections first!

Orings if required second!

Injectors if required third!