Odd LCA/ball joint combo

#12

>>1965 Ford Mustang Fastback (sold 1984)

>>2007 Beagle Male Tricolor (RIP My oldest friend)

>>2007 Beagle Female Tricolor (RIP My sweet girl)

I love your signature, I should add my fave dogs to my signature as well, I just lost a 18 yr old Perro Cimmaron female last year, the best dog I've ever had out of ten...And perhaps my favorite car was also a 1966 Mustang Fastback with the K-code 289 and pony interior, in an ironic twist given this thread it wrecked due to a lower ball joint separation and ensuing wheel fold-up....although those cars were total pieces of doggie doo structurally, what a lot of fun!

More on topic with this thread is my plan of attack moving forward:

1) I plan to get a 20.5 mm reamer and open up the squashed bores in the knuckle while holding the slot open with an 0.032" shim. I am absolutely unconcerned about removing 0.25 mm (<0.010") from the wall of that bore, strength-wise, and I believe it is safer than stressing the integrity of the knuckle overcoming the elastic limit of the aluminum to get back to a 20.5 mm bore.

2) I await a reply from OTTP regarding their "Cobalt Ball Joint (2008-2010 LNF)" stud diameter, that will determine my next move. If it is 20.5 I'll get a pair and replace the BJ90415s I just put in my old LCAs.

3) If OTTPs BJ are the same old 20 mm units everyone else has I will mill some sleeves with slots and bolt clearance and use the new BJ90415s already in the LCAs.

I appreciate everyone sharing links to similar discussions, I find it odd although the OTTP LNF BJs are mentioned a few times, no one ever reports back whether they are correct for HHR SS/FE5 or not...

Thanks a lot GM.

Howie

>>2007 Beagle Male Tricolor (RIP My oldest friend)

>>2007 Beagle Female Tricolor (RIP My sweet girl)

I love your signature, I should add my fave dogs to my signature as well, I just lost a 18 yr old Perro Cimmaron female last year, the best dog I've ever had out of ten...And perhaps my favorite car was also a 1966 Mustang Fastback with the K-code 289 and pony interior, in an ironic twist given this thread it wrecked due to a lower ball joint separation and ensuing wheel fold-up....although those cars were total pieces of doggie doo structurally, what a lot of fun!

More on topic with this thread is my plan of attack moving forward:

1) I plan to get a 20.5 mm reamer and open up the squashed bores in the knuckle while holding the slot open with an 0.032" shim. I am absolutely unconcerned about removing 0.25 mm (<0.010") from the wall of that bore, strength-wise, and I believe it is safer than stressing the integrity of the knuckle overcoming the elastic limit of the aluminum to get back to a 20.5 mm bore.

2) I await a reply from OTTP regarding their "Cobalt Ball Joint (2008-2010 LNF)" stud diameter, that will determine my next move. If it is 20.5 I'll get a pair and replace the BJ90415s I just put in my old LCAs.

3) If OTTPs BJ are the same old 20 mm units everyone else has I will mill some sleeves with slots and bolt clearance and use the new BJ90415s already in the LCAs.

I appreciate everyone sharing links to similar discussions, I find it odd although the OTTP LNF BJs are mentioned a few times, no one ever reports back whether they are correct for HHR SS/FE5 or not...

Thanks a lot GM.

Howie

#13

If you decide to replace the knuckles, they are listed as unavailable, but a Google search may turn something up.

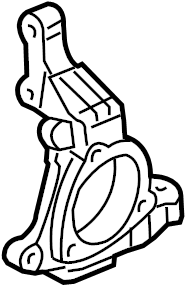

Steering Knuckle

Part Number: 25923941Supersession(s): 25796695

KNUCKLE - STEERING.

KNUCKLE - STEERING.W/SS. W/SS model.

Fits Cobalt, HHR

Cobalt; w/SS Model; Right. HHR; w/SS; Right. W/SS. W/SS model.

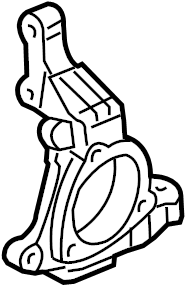

Steering Knuckle

Part Number: 25923942Supersession(s): 25796696

KNUCKLE - STEERING.

KNUCKLE - STEERING.Steering Knuckle. W/SS. W/SS model.

Fits Cobalt, HHR

Cobalt; w/SS Model; Left. HHR; w/SS; Left. W/SS. W/SS model.

#14

It does say in the description of the part I linked to:

This is an OEM replacement ball joint for the LNF Cobalt and HHR. These feature a 20.5mm ball joint stud diameter.

So I would expect them to be correct.

This is an OEM replacement ball joint for the LNF Cobalt and HHR. These feature a 20.5mm ball joint stud diameter.

So I would expect them to be correct.

#16

Have a good T'day folks!

Howie

#17

#18

PSA (again,) RPO codes do not mean the exact same thing across years and models. Assuming otherwise causes much trouble.

In this case, all HHR SS and 208-2010 Cobalt SS carry RPO FE5 and use the same 20.5 mm ball joint on indentical LCA's, and got identical knuckles (and SOME other common parts,) but any prior year Cobalt carrying FE5 had 19.6 mm ball joints.

... It would be somewhat trivial to take a flat cold chisel (I have a super sharp set of Snap-Ons) and re-open the knuckle, but I am worried about fatigue to the aluminum of the knuckle, and aluminum (depending on alloy) can suffer from cold-working fatigue. Do any of you remember anyone attempting this? A failure of the knuckle at the lower ball joint would be catastrophic on the highway. From this perspective it may be better to get a 20.5 mm reamer and open the bore back up with a smaller slot.

I'm not disagreeing withe reamer idea, if the clamp bolt holes are still straight enough. Good to do it anyway, may be needed, maybe a little of both (un) bending and reaming, especially if you have an adjustable reamer in the range. Better be a spiral reamer tho, because of the slot. Having the correct reamer made would be $$$, I suppose MAYBE someone stocks one.

Salvage the knuckles. New ones are gone. Boneyard finds are rare. There is much need, thanks to parts purveyor screwups and careless mechanics.

Last edited by PulpFriction; 11-19-2023 at 02:06 PM.

#20

I'd rather tank the knuckles to clean them up, take a set of ID gauges to them to analyze the bores, and look for stress and potential cracking. If I do have to clean the bores up at all I can do it better on the mill than chucking a reamer in a hand drill or turning it by hand. I'm going to have some thinks on this over turkey this week...

Cheers!

Howie