Installing an Oil Catch Can

#262

Don't bother cutting a PCV up to see what's inside. It is a simple piece of flat flopping up & down on a hole. I guess some engineer somewhere figures out the weight of the flat and the sizes of the in/out pipes.

That's why I never understood why a "tune-up" always included a new PCV. Some oil solvent (gasoline) cleans any gunk out just fine. You really need to abuse an engine to build up enough gunk to clog that size hole.

FWIW, sintered filters come in various micron ratings and materials. If you go to a homebrew store you can easily get a SS filter/stone, we use them for Oxygen and CO2. I am thinking maybe one designed for filtering air is too small a rating to filter oil vapor, thus clogging very quickly.

As usual; McMaster-Carr is a good source.

That's why I never understood why a "tune-up" always included a new PCV. Some oil solvent (gasoline) cleans any gunk out just fine. You really need to abuse an engine to build up enough gunk to clog that size hole.

FWIW, sintered filters come in various micron ratings and materials. If you go to a homebrew store you can easily get a SS filter/stone, we use them for Oxygen and CO2. I am thinking maybe one designed for filtering air is too small a rating to filter oil vapor, thus clogging very quickly.

As usual; McMaster-Carr is a good source.

#263

McMaster-Carr

My catch cans are all pieces ordered from mcmaster. Love that place! That's a link to the breather vents, male or female, in almost any size. It's what the mini cans have in them now.

My catch cans are all pieces ordered from mcmaster. Love that place! That's a link to the breather vents, male or female, in almost any size. It's what the mini cans have in them now.

#264

#265

Alright, who has the dunce cap, pass it over. The check valve I had installed in the line to the turbo vacuum source was backwards, so very little vapor and pressure could escape while in boost condition. The fact that the check valve had failed and was allowing a little air to flow against the design of the valve, at least allowed a little pressure and vapor to escape to the catch can.

So I'm very relieved that I found the problem, wish I hadn't driven 4,000 miles like that, but dang it. Humans make mistakes, everyone - test your check valves and really think about what is going on, making sure that air is flowing only one way through the valve and towards the vacuum source.

Now I know phases 2 and 3 are still worthy of testing, and I will revisit.

So I'm very relieved that I found the problem, wish I hadn't driven 4,000 miles like that, but dang it. Humans make mistakes, everyone - test your check valves and really think about what is going on, making sure that air is flowing only one way through the valve and towards the vacuum source.

Now I know phases 2 and 3 are still worthy of testing, and I will revisit.

Last edited by RJ_RS_SS_350; 07-18-2016 at 07:12 PM. Reason: punctuation

#266

Alright guys, I'm frustrated. I ordered up a couple of the check valves that DrLoch linked to, got 1 installed(correctly) and 1 spare.

Configured system to phase 4. Still oil vapor escaping out the oil filler cap. Reconfigured system to phase 1 (had no problem with phase 1 when I started all this). Still oil vapor escaping out the oil filler cap.

So I tried a new O-ring on the filler cap. No help.

Then I wondered if maybe the blow-by has gotten worse. I performed another cylinder leakdown test, but got precisely the same results as before, so it doesn't seem to be that. 2% on cylinders 1, 2, and 3; 5% on cylinder 4.

None of the catch can lines are clogged, I even tested the check valve(and line) on the fresh air in line to port 1, but it's functioning properly, too.

I think I need to abandon the catch can on the turbo side, go back to just a short line from port 2 to the turbo. At least as a test, if it quits blowing vapor past the filler cap, I'll know the problem is only at boost.

Tell me what you think of all this. I'm also thinking about a vacuum pump, but is the oil vapor that gets past the catch can going to ruin a vacuum pump, or is there some kind of safeguard against that? Does the pump run all the time, or is there a sensor that turns it on when manifold vacuum drops?

Configured system to phase 4. Still oil vapor escaping out the oil filler cap. Reconfigured system to phase 1 (had no problem with phase 1 when I started all this). Still oil vapor escaping out the oil filler cap.

So I tried a new O-ring on the filler cap. No help.

Then I wondered if maybe the blow-by has gotten worse. I performed another cylinder leakdown test, but got precisely the same results as before, so it doesn't seem to be that. 2% on cylinders 1, 2, and 3; 5% on cylinder 4.

None of the catch can lines are clogged, I even tested the check valve(and line) on the fresh air in line to port 1, but it's functioning properly, too.

I think I need to abandon the catch can on the turbo side, go back to just a short line from port 2 to the turbo. At least as a test, if it quits blowing vapor past the filler cap, I'll know the problem is only at boost.

Tell me what you think of all this. I'm also thinking about a vacuum pump, but is the oil vapor that gets past the catch can going to ruin a vacuum pump, or is there some kind of safeguard against that? Does the pump run all the time, or is there a sensor that turns it on when manifold vacuum drops?

#267

Once again, I know nothing about Turbo.

Sound to me you're thinking back wards. Don't you want No pressure going into the crankcase? Just normal compression pushing the fumes out at a leisurely rate, if at all.

Seems like you are trying to force oil vapor out of the crankcase, when it wants to leave on its own. The point of the PCV is to let the vapor out (if wants out) without letting it get into the atmosphere by burning it, not trying to force it back into the flow.

The point of your catch can is to separate the vapor and the air, catching the oil. As long as that is happening who cares where the clean air is going. You could just vent to atmosphere.

Then the other bit is when the boost cuts off. IIRC, that is the reason for 2 PCV on the stock SS. One for boost and one for abrupt loss of boost, opposite directions.

Like I said, I don't know nuthin'. And I don't even drink anymore.

Sound to me you're thinking back wards. Don't you want No pressure going into the crankcase? Just normal compression pushing the fumes out at a leisurely rate, if at all.

Seems like you are trying to force oil vapor out of the crankcase, when it wants to leave on its own. The point of the PCV is to let the vapor out (if wants out) without letting it get into the atmosphere by burning it, not trying to force it back into the flow.

The point of your catch can is to separate the vapor and the air, catching the oil. As long as that is happening who cares where the clean air is going. You could just vent to atmosphere.

Then the other bit is when the boost cuts off. IIRC, that is the reason for 2 PCV on the stock SS. One for boost and one for abrupt loss of boost, opposite directions.

Like I said, I don't know nuthin'. And I don't even drink anymore.

#268

Sorry it's been so long. Things have been hectic at work to say the least. My catch cans and setup haven't changed. I'll bet we've got close to 1000 miles on it now. Still running mini versions of the design I'm fabricating.

I'm not certain here, no one is! But vapor shouldn't be escaping from the oil filler, that's for sure! I have the valve cover and oil filler in plain sight. There's dust, no signs of any leakage. The charge system is now 100% dry and the cans are doing what they're intended. Albeit probably not the best, because this mini version is only a sintered filter with copper mesh. The finished product is twice it's size with a filtering chamber in between.

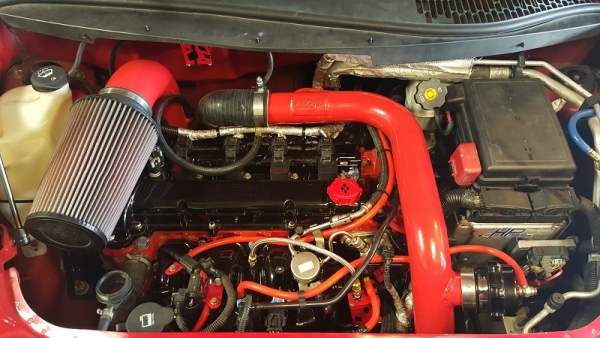

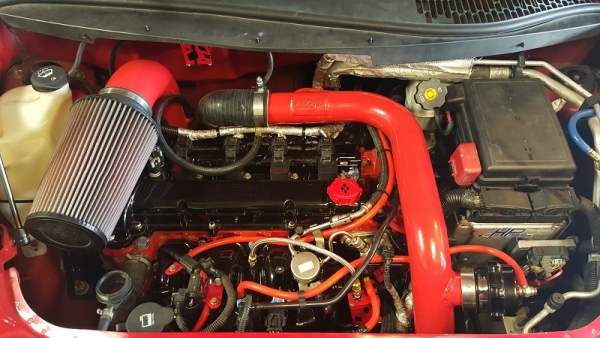

This would be my stage 1;

CAI --> Homemade PCV --> Port 1 (Fresh air in)

Port 2 --> Catch Can --> Cheap vacuum check --> Turbo

PCV bypass (with intake manifold plugged) --> Catch Can --> Cheap vacuum check --> A heater hose T(from a flush kit) with various pieces of tubing and hose to reduce to 1/4" silicon tubing. Not pretty, but it's effective.

All the tubing is 1/4" silicon, with the exception of the fresh air. The ZZP intake has a 3/8" barb on it. Fittings are 1/4" barb to NPT.Once I have the finished product, all the lines will be -4AN with NPT/AN fittings.

You can see most of the setup here, once I get to my laptop I can edit the pic. There's one can ziptied to the firewall, and another ziptied to the bottom right portion of the intake manifold. You can't see the in-line pcv for fresh air, it blends with the 3/8" hose.

I'm not certain here, no one is! But vapor shouldn't be escaping from the oil filler, that's for sure! I have the valve cover and oil filler in plain sight. There's dust, no signs of any leakage. The charge system is now 100% dry and the cans are doing what they're intended. Albeit probably not the best, because this mini version is only a sintered filter with copper mesh. The finished product is twice it's size with a filtering chamber in between.

This would be my stage 1;

CAI --> Homemade PCV --> Port 1 (Fresh air in)

Port 2 --> Catch Can --> Cheap vacuum check --> Turbo

PCV bypass (with intake manifold plugged) --> Catch Can --> Cheap vacuum check --> A heater hose T(from a flush kit) with various pieces of tubing and hose to reduce to 1/4" silicon tubing. Not pretty, but it's effective.

All the tubing is 1/4" silicon, with the exception of the fresh air. The ZZP intake has a 3/8" barb on it. Fittings are 1/4" barb to NPT.Once I have the finished product, all the lines will be -4AN with NPT/AN fittings.

You can see most of the setup here, once I get to my laptop I can edit the pic. There's one can ziptied to the firewall, and another ziptied to the bottom right portion of the intake manifold. You can't see the in-line pcv for fresh air, it blends with the 3/8" hose.

#269

Once again, I know nothing about Turbo.

Sound to me you're thinking back wards. Don't you want No pressure going into the crankcase? Just normal compression pushing the fumes out at a leisurely rate, if at all.

Seems like you are trying to force oil vapor out of the crankcase, when it wants to leave on its own. The point of the PCV is to let the vapor out (if wants out) without letting it get into the atmosphere by burning it, not trying to force it back into the flow.

The point of your catch can is to separate the vapor and the air, catching the oil. As long as that is happening who cares where the clean air is going. You could just vent to atmosphere.

Then the other bit is when the boost cuts off. IIRC, that is the reason for 2 PCV on the stock SS. One for boost and one for abrupt loss of boost, opposite directions.

Like I said, I don't know nuthin'. And I don't even drink anymore.

Sound to me you're thinking back wards. Don't you want No pressure going into the crankcase? Just normal compression pushing the fumes out at a leisurely rate, if at all.

Seems like you are trying to force oil vapor out of the crankcase, when it wants to leave on its own. The point of the PCV is to let the vapor out (if wants out) without letting it get into the atmosphere by burning it, not trying to force it back into the flow.

The point of your catch can is to separate the vapor and the air, catching the oil. As long as that is happening who cares where the clean air is going. You could just vent to atmosphere.

Then the other bit is when the boost cuts off. IIRC, that is the reason for 2 PCV on the stock SS. One for boost and one for abrupt loss of boost, opposite directions.

Like I said, I don't know nuthin'. And I don't even drink anymore.

At idle, it's not really a problem. Not much blow-by(pressure), lots of vacuum(19") to help evacuate. But when boosting, it's a problem, more blow-by, more pressure, and complete loss of manifold vacuum. So we send it to the turbo, but that provides very little suction. I measured only 4" vacuum at moderate boost.

So more pressure, less vacuum. Then I have that little problem with cylinder #4, even more blow-by, even more pressure.

I would guess that the crankcase pressure I had after blasting the intake valves was right at the threshold of the systems ability to evacuate. The cylinders may have worn just the slightest amount since then, exceeding that threshold. The only way to escape was past the oil filler O-ring.

We're directing the clean air into the intake system, I don't think we want to vent to atmosphere, it's all metered air, right?

#270

Why do you want the vapor out of the crankcase? Won't it condense back to oil?

'57 Chevys did just fine with metal wool stuffed into the filler cap for condensate medium.

The air isn't metered if it doesn't pass a meter, i.e.: crankcase ventilation does not pass the MAF, or there would be trouble.

In the stock configuration; is air directed to the crankcase, or just blow by?

I don't know nuthin', just trying to learn.

'57 Chevys did just fine with metal wool stuffed into the filler cap for condensate medium.

The air isn't metered if it doesn't pass a meter, i.e.: crankcase ventilation does not pass the MAF, or there would be trouble.

In the stock configuration; is air directed to the crankcase, or just blow by?

I don't know nuthin', just trying to learn.